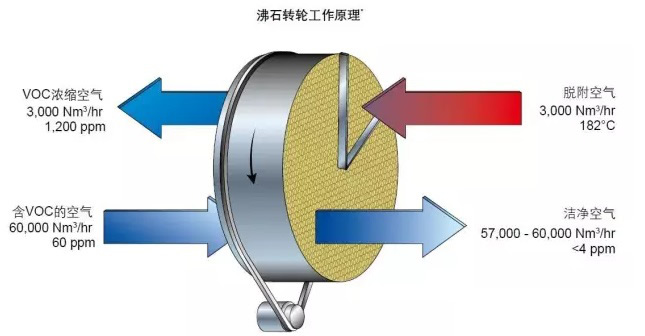

01workingprinciple

Whentheairtobetreated(withsolvent)passesthroughthezeoliterunner,theVOCsinthegasstreamareadsorbedbythehydrophobiczeolite.Thecleanairisthendischargedintotheatmospherethroughtherunner. Thezeoliterunnerrotatescontinuously,transferringtheadsorbedVOCstothedesorptionarea.Inthedesorptionarea,theVOCsadsorbedonthezeoliterunneraredesorbedbyaheatedairstream,whichaccountsfor5to10%ofthetotaltreatedairvolume.Afterthat,thedetachedrunnerturnsbacktotheprocessingarea. Normally,theconcentratedVOCswillbetransferredtotheoxidativecombustionsystem,andtheVOCswillbedecomposedintowatervaporandcarbondioxide.TheenergyofVOCsisusedintheoxidation(combustion)process,whichfurtherreducesthefuelrequired.

02Maintenance-freeself-cleaningwithoutleakage

Ourcompanyusesauniquetechnology,madeofcorrugatedmineralfibersubstratessynthesizedbyothermachinematerials,withphysicalintegrity,hardnessandsufficientflexibilitytowithstandhighthermalstress. Inaddition,theuniquetechnologyofthezeoliterunnercanwithstandhightemperaturesupto593.33°C,theairflowthroughthehoneycomboftherunnerisuniform,lowspeed,andthepressuredropisverylow(lessthan300Pa). Thesystemhasonlyasmallnumberofmovingparts,andthereisnowearoftheadsorbent.Itcanoperatecontinuouslyforalongtimetoensurestableoutput.Thefrictioncoefficientofthesealingringequippedwiththerunnerisextremelysmall,whichcancompletelyavoidleakage. AheatexchangercanalsobeaddedtothesystemtopreheatconcentratedVOCstoprovidethezeoliterunnerwiththeheatrequiredforitsdesorptionandimprovefuelefficiency.